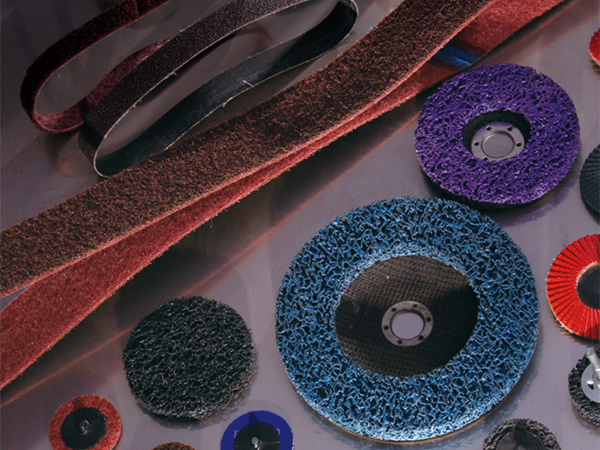

Winking is one of leading Asian abrasive manufacturers.Throughout the world, industrial companies , work-shops and individual users rely on the permanent high product quality.

WINKING develops standard products for normal uses ,and special products for individual solutions for specific abrasives tasks.

Development and manufacturing are part of an integrated quality management system of WINKING. part:Development and manufacturing are part of an integrated quality management system of WINKING Factory .Only high-quality raw material are used and all materials are tested by a strict quality control .The single manufacturing steps include a complex and safe quality check .Only high-quality raw material are used and all materials are tested by a strict quality control .The single manufacturing steps include a complex and safe quality check .

|

SUPPLIER PROFILE |

|||||||||||||||||||||||||||||

|

GENERAL INFORMATION |

|||||||||||||||||||||||||||||

|

Factory |

WINKING ABRASIVES CO .,LTD |

||||||||||||||||||||||||||||

|

Contact person & Telephone |

TEL : 0086-579-87291788 FAX : 0086-579-87111948 |

||||||||||||||||||||||||||||

|

Website & Email address |

www.winkingde.com / www.abrasivesde.com |

||||||||||||||||||||||||||||

|

Business type |

|

||||||||||||||||||||||||||||

|

History |

1982~2020 |

||||||||||||||||||||||||||||

|

PRODUCTS AND SALES INFORMATION |

|||||||||||||||||||||||||||||

|

Products |

Resin Abrasives | Other Abrasives | |||||||||||||||||||||||||||

|

Monthly capacity |

9700000pcs | 1500000 pcs | |||||||||||||||||||||||||||

|

Monthly output |

9000000pcs | 1000000 pcs | |||||||||||||||||||||||||||

|

Total sales in 2018 |

75000000pcs | 9000000 pcs | |||||||||||||||||||||||||||

|

Total sales in 2019 |

85000000pcs | 12000000 pcs | |||||||||||||||||||||||||||

|

Total sales for North America market in 2019 |

9% | ||||||||||||||||||||||||||||

|

Total sales for Middle East market in 2019 |

16% | ||||||||||||||||||||||||||||

|

Total sales for Europe market in 2019 |

25% | ||||||||||||||||||||||||||||

|

Total sales for South America market in 2019 |

27% | ||||||||||||||||||||||||||||

|

Total sales for Asia market in 2019 |

23% | ||||||||||||||||||||||||||||

|

Major US customers |

Europe , Middle East , Asia , South America , Africa | ||||||||||||||||||||||||||||

|

ISO certificate |

IS9001 | ||||||||||||||||||||||||||||

|

Quality standard |

Germany MPA , JB/T6353 | ||||||||||||||||||||||||||||

|

PRODUCTION INFORMATION |

|||||||||||||||||||||||||||||

|

Factory |

Factory area | Employee No. | Workshop | ||||||||||||||||||||||||||

|

general factory |

700002 | 500 | 8X300002 | ||||||||||||||||||||||||||

|

Shifts No. |

1D |

||||||||||||||||||||||||||||

|

Produce process |

*********************************** |

||||||||||||||||||||||||||||

|

Outsourced parts |

*********************************** |

||||||||||||||||||||||||||||

|

Manufacturing Equipment list |

|

||||||||||||||||||||||||||||

| ENGINEERING & MANAGEMENT | |||||||||||||||||||||||||||||

|

R&D manpower |

8 |

||||||||||||||||||||||||||||

|

R&D procedure |

YES |

||||||||||||||||||||||||||||

|

R&D time |

15 DAY |

||||||||||||||||||||||||||||

|

MRP system used |

YES |

||||||||||||||||||||||||||||

|

Patents owned |

YES |

||||||||||||||||||||||||||||

|

QUALITY |

|||||||||||||||||||||||||||||

|

QC manpower |

YES

|

||||||||||||||||||||||||||||

| Gauging & Calibration | YES | ||||||||||||||||||||||||||||

| Incoming inspection | YES | ||||||||||||||||||||||||||||

| In-process inspection | YES | ||||||||||||||||||||||||||||

| Final function inspection | YES | ||||||||||||||||||||||||||||

| Final packaging inspection | YES | ||||||||||||||||||||||||||||

| Test item | YES | ||||||||||||||||||||||||||||

| Life Test Available? | YES | ||||||||||||||||||||||||||||

| Test facilities |

Physice checking report:> Aspect> Dimension> Tolerance of Externality> Imbalance At static> GyrationIntensity |

||||||||||||||||||||||||||||

| Test data record | YES | ||||||||||||||||||||||||||||

| Defective products handling | Reject &Callback | ||||||||||||||||||||||||||||

| Defective reasons analysis | YES | ||||||||||||||||||||||||||||

| Is there a quality improvement system like TQM, lean production, 6 sigma, etc.? | lean production / 6 sigma | ||||||||||||||||||||||||||||

| DELIVERY | |||||||||||||||||||||||||||||

| Reliable logistic process | YES | ||||||||||||||||||||||||||||

| Average lead time | 30 - 45 days | ||||||||||||||||||||||||||||

| Average MOQ | 5000-10000PCS/ITEM | ||||||||||||||||||||||||||||

| DeliveryPort | SHANGHAI/NINGBO/TIANJING | ||||||||||||||||||||||||||||

| Ability to Palletization | YES | ||||||||||||||||||||||||||||

| Door to Door, or CFS | YES | ||||||||||||||||||||||||||||

| Payment Term | TT30% | ||||||||||||||||||||||||||||

| Direct Export or Export by Agent | Direct Export or Export by Agent | ||||||||||||||||||||||||||||

| Ability to communicate in English? | YES | ||||||||||||||||||||||||||||