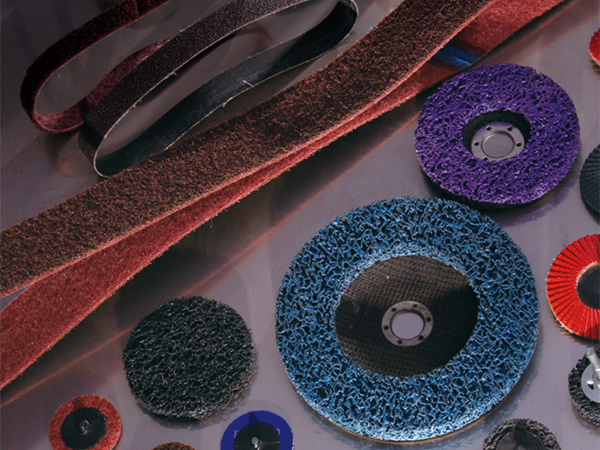

Non-woven Flap Disc-rough

100x16

- Code:PFD100NW

Many factors of non-woven abrasive are in the radioactive arrangement, each layer comnes into line and be compacted, ensure long working life.

VIDEOS

-

PEGATEC SPECIAL SPARK IN 2021 CHRISTMAS

PEGATEC SPECIAL SPARK IN 2021 CHRISTMAS -

PEGATEC IS ART

PEGATEC IS ART -

One of the best-selling pegatec products 115x1x22mm SHARP & DURABLE!!

One of the best-selling pegatec products 115x1x22mm SHARP & DURABLE!! -

PEGATEC serves world-class engineering

PEGATEC serves world-class engineering -

Fighting against piracy

Fighting against piracy -

Discover PEGATEC

Discover PEGATEC -

pegatec upgrade formula super awesome!

pegatec upgrade formula super awesome! -

Take a look at pegtaec's face mask

Take a look at pegtaec's face mask -

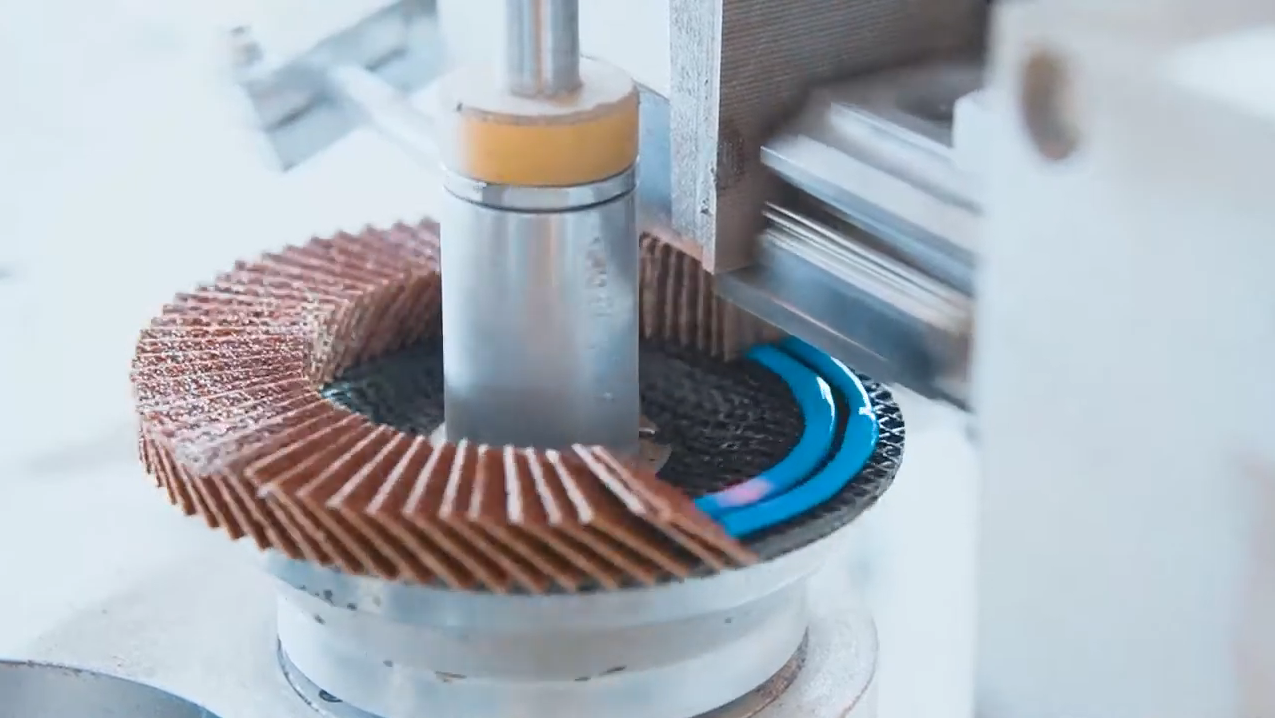

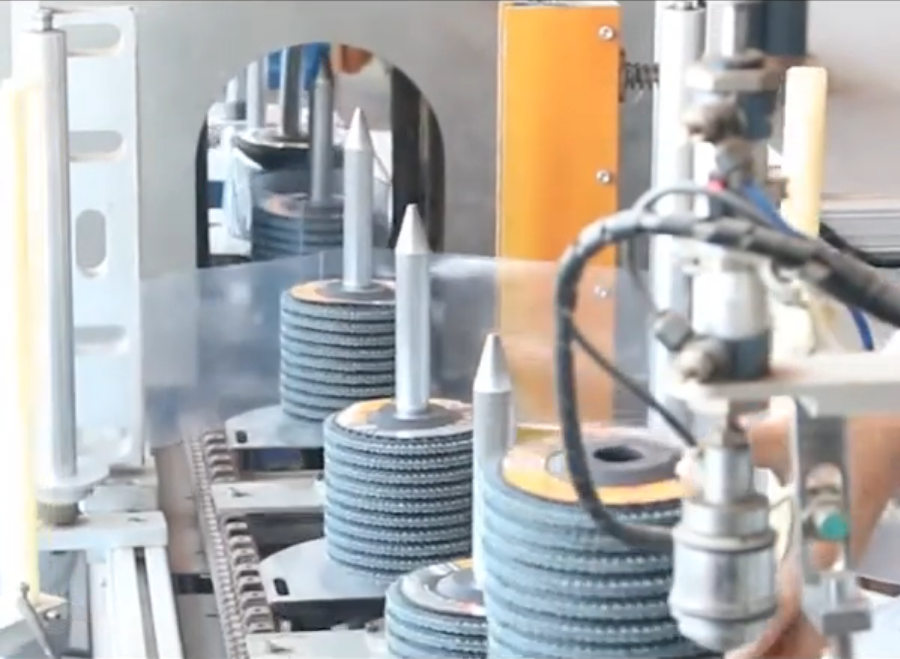

Let's find out how the flap disc is made

Let's find out how the flap disc is made -

PEGATEC ABRASIVES resume production!

PEGATEC ABRASIVES resume production! -

Why are our flap discs of good quality and high output-let's find out

Why are our flap discs of good quality and high output-let's find out -

Difference of 70m / 80m cutting disc

Difference of 70m / 80m cutting disc

Details

Many factors of non-woven abrasive are in the radioactive arrangement, each layer comnes into line and be compacted, ensure long working life

Fine grinding of big surface

Clear blue material

Weld joint clean of stainless steel element

Surface working of processing equipments and trunk & tank after manufacture and assembly

Alumina oxide abrasives

Coarse=Yellow Medium=Red Fine=Blue

Coarse=Yellow Medium=Red Fine=Blue

![]()

|

Product Advantages

High flexibility

High abrasive ratio brought by coated abrasive.

Even blades loss, and no residue on the work-piece.

Special structure of flap wheel with shaft makes closer working to the work-piece.

|

Application

Tools, mould and fine grinding.

Trunk, tin and difficult contact area grinding in manufacturing processing equipment.

Non-ferrous metal or light weight alloy valve and accessories precision finishing.

|

Usage Advice

Perform best grinding at 15-20m/s speed. Obtain best balance of grinding ability, surface fine finishing quality, low work-piece temperature.

Different material with corresponding grinding oil can highly increase the coated abrasives working life

|

||

|

|

|

|

|

|

|

Affecting factors of grinding |

||||

|

Tool wearing and work-piece temperature load |

|

Material grinding ratio |

|

Surface roughness |

|

Decrease grinding pressure, circular velocity and add grinding oil can low tool wearing and down temperature of work-piece |

|

To gain higher grinding ratio, suggest to use rough grit instead of increasing contacting pressure. |

|

Apply high grinding speed could gain bright and clean surface. Increasing contact pressure leads to more coarse surface. |

![]()

![]()

| Size |

Grades Available |

PCS/BOX | PCS/CTN | M/S | EAN-CODE | |

| Dia | Material | |||||

| 100x16 |

Aluminum Oxid |

Coarse |

20 | 200 | 80m/s | PFD100NW |

| 115x22,23 | 20 | 100 | 80m/s | PFD115NW | ||

| 125x22,23 | 20 | 100 | 80m/s | PFD125NW | ||